Why is temperature monitoring of refrigerated containers essential?

Unlike dry shipping containers, refrigerated containers, also known as reefers, are transported on vessels and through dedicated ports and terminals specially equipped to handle the reefer’s unique requirements.

Overseas reefer shipments can take weeks to complete their journey, so maintaining the correct temperature settings on each container is critical. What’s more, and for various reasons, these mechanical refrigeration units can fall off of their initial set-point at any time during their trip. So routine inspections, quite often manual, are essential to ensure the viability of each load.

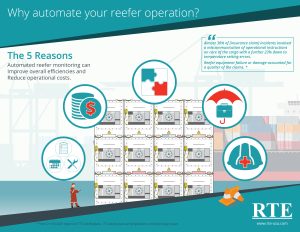

But there are many pitfalls to manual inspections and accurate record-keeping that can set up reefer operators for potential failure. And this is why automated temperature monitoring of reefer containers is an essential tool for refrigerated container operators of any size.

Insurance Claims Reduction

The business of transporting refrigerated containers is vital to our global food and pharmaceutical supply chain. Perishable goods shipped in refrigerated containers require precise control over the temperature settings over weeks of seagoing transportation. And complicating the matter, shipments of blueberries, bananas, proteins, and Covid 19 vaccines each have different requirements for maintaining acceptable interior atmospheric set-points.

The business of transporting refrigerated containers is vital to our global food and pharmaceutical supply chain. Perishable goods shipped in refrigerated containers require precise control over the temperature settings over weeks of seagoing transportation. And complicating the matter, shipments of blueberries, bananas, proteins, and Covid 19 vaccines each have different requirements for maintaining acceptable interior atmospheric set-points.

Terminals and vessels must maintain perishable cargo integrity while the reefer containers are in their care. So understanding if each container is, or is not, properly functioning is critical. Should a reefer fall out of temperature spec and its valuable contents spoil, tens of thousands of dollars may be at stake.

What’s important to understand is that 30% of all refrigerated transport insurance claims are due to the miscommunication of operational instructions, temperature setting errors, and reefer equipment mechanical failures*

Yet many of these challenges and subsequent losses are often mitigated through automated and remote monitoring of refrigerated containers.

Insurance claim costs are not only financial. Loss of trust and future business can linger for years. Automatic reefer monitoring protects your customer’s assets through central management of all reefer settings and by alerting your team in real-time, managing and avoiding a claim from happening in the first place. In addition, the electronic storage of all monitored data protects you should any insurance claim arise.

RTE provides many types of reefer monitoring solutions based on the unique requirements of each terminal or vessel operation.

*as cited in an Oct 2020 TT Club report.

Personnel Safety

No one wants to have an accident, especially one involving human injury. And today’s fast-paced port environments require workers to maintain precise attention and care to safety while working. Yet, unlike dry containers, refrigerated containers require more human interaction. Therefore, no matter the weather conditions, routine inspections, and data collection are essential to ensuring each reefer is operational and maintains the proper settings, a practice that increases the possibility of personal risk.

No one wants to have an accident, especially one involving human injury. And today’s fast-paced port environments require workers to maintain precise attention and care to safety while working. Yet, unlike dry containers, refrigerated containers require more human interaction. Therefore, no matter the weather conditions, routine inspections, and data collection are essential to ensuring each reefer is operational and maintains the proper settings, a practice that increases the possibility of personal risk.

An automated system for remotely recording reefer data and managing set-points and other variables reduces pedestrian traffic in the container yard, improving human safety.

Value-Added Benefits

From a marketing standpoint, having a reliable automatic reefer monitoring system adds incredible value to your overall service offering allowing your operation to stand apart from competitors.

From a marketing standpoint, having a reliable automatic reefer monitoring system adds incredible value to your overall service offering allowing your operation to stand apart from competitors.

The ability to package and present your customers with a complete historical view of reefer performance while in your care is a valuable asset worth sharing.

RTE’s modular monitoring system can also record power consumption data for each refrigerated container, building trust by providing accurate data for invoicing the amount of power used instead of an estimated figure.

Increased Efficiency

Everyone has been trying to do more with less lately. Fortunately, automated reefer monitoring provides your team with an additional time-saving tool for resolving problems quickly and efficiently. Additionally, with centralized management of monitored reefer alerts and notifications, your team has the power to direct attention to terminal needs more effectively.

Everyone has been trying to do more with less lately. Fortunately, automated reefer monitoring provides your team with an additional time-saving tool for resolving problems quickly and efficiently. Additionally, with centralized management of monitored reefer alerts and notifications, your team has the power to direct attention to terminal needs more effectively.

RTE’s GRASP3.0 Server Software and GrAsPP mobile application put reefer management in the hands of key personnel on your team.

Data Integration

Information is power for stakeholders in your terminal operation, and accurately incorporating data from the reefer operation into terminal-wide decision-making not only improves overall performance but also enhances the bottom line. Automated reefer monitoring systems that integrate with your existing Terminal Operating System (TOS) make this data collaboration easy.

Information is power for stakeholders in your terminal operation, and accurately incorporating data from the reefer operation into terminal-wide decision-making not only improves overall performance but also enhances the bottom line. Automated reefer monitoring systems that integrate with your existing Terminal Operating System (TOS) make this data collaboration easy.

GRASP™3.0 integrates with ANY available TOS through XML and JSON interfacing and is Navis N4 ready without additional configuration requirements.

Contact RTE for more information on an automated monitoring solution that’s custom-designed for your reefer terminal, yard, or vessel operation. Together we can help you achieve more efficient, money-saving, and safe refrigerated container handling.

Did you like what you just read?