How Remote Reefer Monitoring Works

Why it matters: The Tangible Benefits for Reefer Terminals

It’s surprisingly common for some terminal operators to be seasoned in reefer handling yet unfamiliar with how automated monitoring actually works. For some, it’s a new part of their role. For others, manual inspections have been the norm for so long that this technology feels foreign—even though it’s been quietly transforming operations in yards around the world.

Perhaps this resonates with your team. Let’s dive in and explore it.

But first, what is Remote Reefer Monitoring?

Remote, or automated, reefer monitoring systems deliver continuous, real-time visibility into refrigerated container conditions—monitoring temperature, power consumption, and alarms remotely. This automation enables a more efficient use of available labor across the terminal, minimizes cargo loss, and enhances overall terminal performance, including accuracy.

Inside the System: Here’s How Automated Reefer Monitoring Operates

Here’s how automated reefer monitoring works and why it’s such a game-changer in cold chain logistics.

The architecture of a typical automated reefer monitoring system centers on three key components: hardware monitoring devices, a software database, and the reefer’s onboard controller—which we’ll highlight below.

The Refrigerated Container (Reefer)

The reefer is THE source of the data to be collected and the factor to be acted upon by terminal personnel. The chief component of this interaction is through the reefer controller.

- The reefer’s onboard computer, called a controller, manages temperature settings inside the container and provides a user interface for these inputs.

- The controller records trip data at regular intervals regarding internal environmental conditions,

- Issues alarms when temperatures exceed pre-set conditions or when mechanical failures occur.

Without automation, accessing this information requires the physical presence of a technician to read the information and write it down or enter it into a tablet. In large reefer terminals, this process can take hours, and rotations may be 4, 6, or 12 hours in between. This sets the stage for data entry errors and delays in alarm notification.

Sensors & Data Collection

- The first level of automated monitoring is delivered through devices that connect to the reefer’s controller to collect all available data, such as temperature, humidity, trip records, alarms, and more.

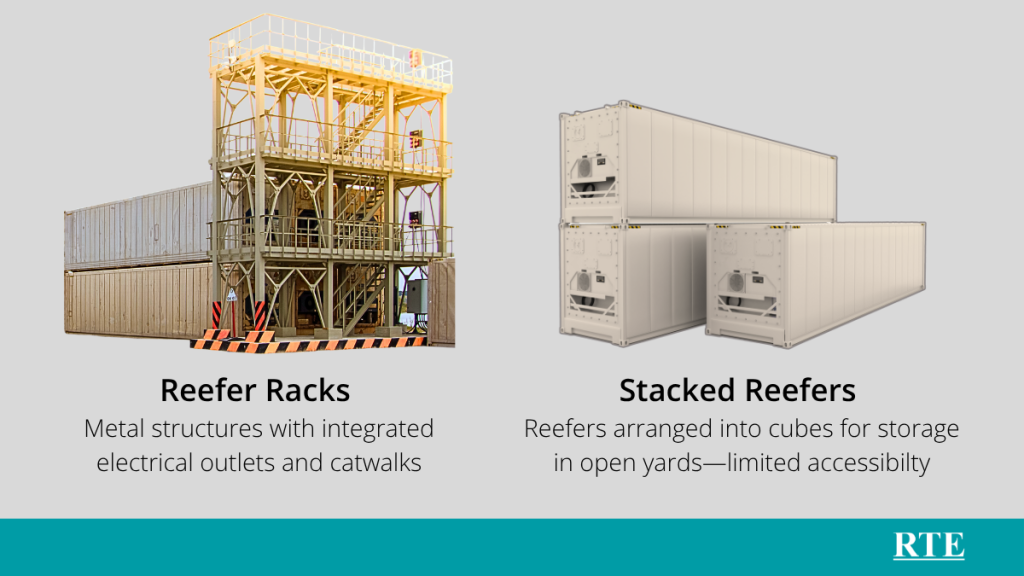

- These devices are either mounted onto racks at each reefer slot or attached directly to each reefer, accessing reefer data directly via a connecting cable to the reefer’s data port.

- When reefers are positioned in the yard, technicians must plug the reefer’s electrical cable into the ground power outlet. At this time, the technician will also connect the monitoring device’s cable to the reefer’s data port.

- Examples: RTE’s BEACON™ Visual Reefer Monitoring system is a rack-mounted solution. WRAD II™ Wireless Reefer Monitoring can be used in either a racked or stacked reefer storage environment.

Connectivity

From Reefer to Monitoring Device to Gateway

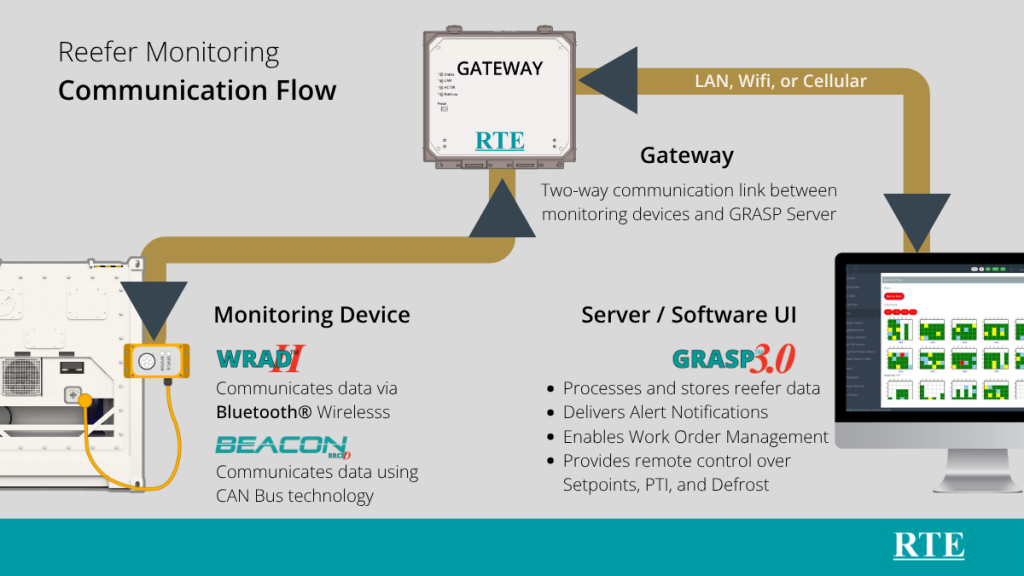

- Collected data from the reefer is then transmitted to a nearby gateway via the monitoring device. Depending on the system, this is done using either wireless or CAN bus technologies.

- Examples: BEACON systems, due to the bright LED lighting capability, rely on ground-power supplies and communicate reefer data with the gateway using a wired connection. WRAD II systems utilize Bluetooth® wireless technology to communicate collected reefer data to the nearest wireless gateway.

From Gateway to Server

- System Gateways act as intermediaries in the two-way flow of information between each connected reefer and the data server and can utilize various forms of communication depending on the terminal network environment, such as Wi-Fi, LAN, or Cellular Modem.

Local or Cloud-Based Platforms

- Data servers running RTE’s GRASP software provide a centralized dashboard to aggregate and analyze the collected data in either local or cloud-based configurations.

- Deviations in temperature, power disconnects, or mechanical failures trigger instant alarms within the system. Each monitoring device transmits the alert to GRASP, which immediately notifies key personnel via alerts, email, and text message.

- Because GRASP is a multi-platform user interface, these alerts are accessible across all connected devices—whether on desktop, tablet, or mobile—ensuring rapid response regardless of location.

Remote Control & Diagnostics

- GRASP reefer monitoring enables terminal managers to remotely address mismatches in key parameters. This includes ensuring reefer setpoints align with the booking setpoints identified in the Terminal Operating System (TOS). This ability enables quick updates and prevents further delays in maintaining correct temperature settings, which can impact cargo quality and the terminal’s reputation for care.

- For example, if a container is booked to maintain -18°C but arrives set to -15°C, the system flags the mismatch and allows instant correction—avoiding delays and preserving cargo quality.

- Operators can adjust temperature setpoints or run diagnostics, defrost, or PTI checks without being physically present.

- Additionally, GRASP integrates with Terminal Operating Systems (TOS) for seamless yard management and greater operational efficiency by combining reefer data with the entire terminal’s container handling processes.

Why Automated Reefer Monitoring Matters: The Tangible Benefits for Terminals

By transitioning from manual inspections to automated reefer monitoring, terminals can enhance their ability to deliver exceptional care for cargo in their yard and increase operational efficiencies, leading to greater profitability. Here are some of the most important ones.

- Real-Time Visibility

Know the exact status of every reefer—location, temperature, energy usage, at any moment, and at a glance through an easy-to-use portal like GRASP. - Proactive Alerts

Temperature spike? The monitoring device flags it, GRASP transmits it, and the alert pings the right team—before cargo feels the heat. These instant notifications for anomalies help prevent spoilage or compliance violations by giving managers detailed information about the issue and the ability to dispatch the right technicians more efficiently. - Energy Efficiency

Track electrical power consumption from each reefer or across specific bays or the entire yard. This information enables the strategic implementation of energy-saving measures, such as peak shaving, to lower utility costs. - Trusted Transparency

Automated logs and reports support audits that can be useful in protecting terminals against false claims of cargo loss. With so many links in the cold chain where failure can occur, having data that proves attention and quality of care were achieved while in your possession is essential. - Reduced Human Error

Automation captures data digitally, on schedule, and accurately every time. This eliminates common discrepancies generally associated with manual data collection practices and missed checks, improving reliability.

See how GRASP reefer monitoring can transform your terminal’s operation—start your demo today.

Latest blog posts

RTE Reintroduces the RTEL Brand of Temperature Indicators and Data Loggers

See how RTE is strengthening cold‑chain visibility across pharmaceuticals, food, and agriculture.

Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment exposes every gap in your cold chain. With risks like rejected cargo or re‑exports, “good enough” monitoring isn’t enough. Here’s how technology can close those gaps and deliver the documentation accuracy you need to succeed.

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.