The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

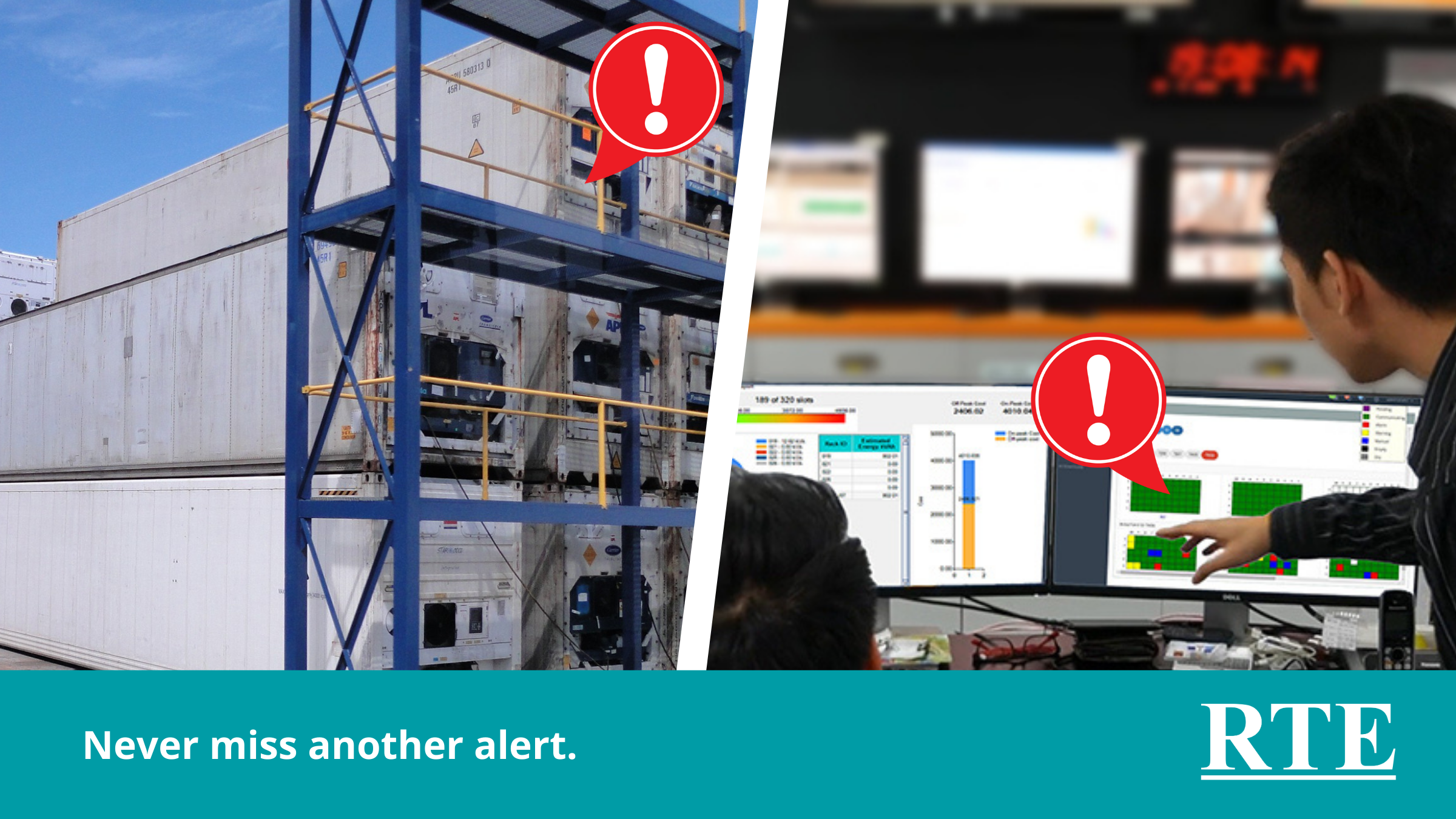

As we approach 2026, reefer operations face rising complexity—from increased cargo volumes and tighter compliance standards to growing pressure for energy efficiency and digital integration. Automated reefer monitoring isn’t just a tech upgrade anymore—it’s a strategic necessity.

But before choosing a system, ask this: “What type of reefer operation are we building?”

At RTE, we guide clients through a four-part framework to help them make smart, scalable decisions. It’s not about chasing features—it’s about solving the right problems, in the right way, for the right yard.

1. Operational Pain Points: What’s Driving the Need?

Start by identifying the core challenges you want to solve. Most clients begin with one concern—like manual inspections—but uncover many more during discovery.

Common pain points include:

- Too many reefers to inspect manually

- Safety risks for yard personnel

- Data entry errors and inconsistent records

- Lack of integration across systems

- No visibility into energy usage or reefer status

Prioritize what matters most. A clear problem definition leads to measurable results.

2. Facility Type: Where Will the System Operate?

Your yard’s layout and handling methods shape your monitoring needs.

- Terminals may use stacks, racks, or hybrids

- Depots often rely on wheeled yards or stacked containers

- Rail yards and vessels/barges introduce mobility and access constraints

No single system fits every yard. Look for providers offering modular solutions that adapt to your environment—not the other way around.

3. Scale of Connectivity: How Many Reefers Are We Talking?

The number of reefer connection points defines the scope of your data project—and your future scalability.

Even if your current volume is manageable, reefer traffic is growing fast. The refrigerated container transport market is projected to grow at a CAGR of 6% to 9% by 2030. Planning for expansion now can save you from costly retrofits later.

4. Communication Infrastructure: What’s Already in Place?

Your yard’s existing network—wired, wireless, or cellular—plays a key role in shaping your monitoring strategy. The good news? Each option has strengths, and the best systems are designed to work with what you’ve got.

- LAN (Cable/Fiber): Offers unmatched stability, speed, and reliability—ideal for high-volume reefer yards and long-term infrastructure

- WLAN (Wireless): Flexible and fast to deploy, especially in dynamic or mobile environments

- WAN (Cellular): Great for remote sites or yards without fixed infrastructure

Understanding your yard’s communication backbone helps ensure seamless data flow and system performance. A quick consult with a systems engineer can help identify any signal challenges or integration opportunities—so your monitoring solution works flawlessly from day one.

Ready to Rethink Reefer Monitoring for 2026?

Whether you’re just starting to explore automation or looking to scale an existing system, the smartest investments begin with the right questions. This framework is designed to help you clarify your needs, avoid costly missteps, and build a monitoring solution that grows with your operation.

At RTE, we don’t just sell hardware and software—we help reefer operators design smarter, safer, more connected yards.

Let’s map your reefer operation together. Schedule a strategy session today.

Latest blog posts

Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment exposes every gap in your cold chain. With risks like rejected cargo or re‑exports, “good enough” monitoring isn’t enough. Here’s how technology can close those gaps and deliver the documentation accuracy you need to succeed.

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

Why Reefer Techs Trust RTE with Complex Controller Repairs

Reefer service techs are pros at diagnosing and fixing mechanical and electrical issues in mobile refrigeration systems. But electronic controllers? That’s a whole different ball game.

Reefer Monitoring: A Smarter Way to Build Trust

What if your reefer data could do more than just keep you informed? Often seen as an internal tool—reefer monitoring, can become a powerful customer-facing asset. Here’s how.