In today’s world of container shipping logistics, tracking workflows and information is essential for staying efficient. Customers rely heavily on terminal operators to handle their cargo successfully, particularly when it involves temperature-sensitive shipments.

Installing an automated reefer monitoring system can really help terminal operators run their operations more smoothly.

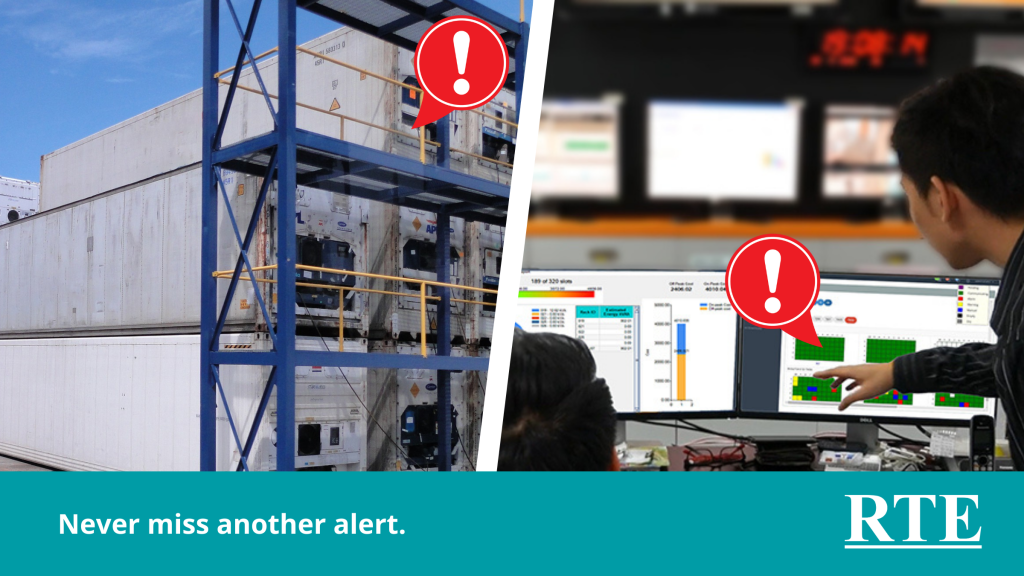

By capturing real-time data on each refrigerated container, operators can quickly respond to out-of-range temperature excursions and receive alerts when containers are plugged in or unplugged. This protects perishable cargo and helps prevent costly claims for damaged goods.

A good reefer monitoring system continuously provides updates and records conditions. This provides a clear and well-documented picture of what’s happening over time. Combining this data with a Terminal Operating System (TOS) further enhances overall efficiency across the entire terminal.

How does remote reefer monitoring integrate into TOS?

To ensure effectiveness and optimize performance, RTE harnesses the power of XML and JSON technology within its GRASP reefer monitoring software. This capability seamlessly interfaces collected reefer data with most TOS software, predominantly used across today’s container terminals. This ensures a synchronized flow of information, enhancing operational efficiency and improving terminal management.

GRASP Remote Reefer Monitoring Displays

What are the benefits of linking remote reefer monitoring with TOS?

When remote reefer monitoring information is integrated with the terminal’s data systems, operators gain a comprehensive view of all activities within the terminal. Additionally, information flows bi-directionally between the Remote Reefer Monitoring (RRM) software and the Terminal Operating System (TOS).

For example, TOS can provide GRASP with lists of incoming reefers and their departure schedules. GRASP then transforms these lists into actionable work orders for plugging in and unplugging reefers as necessary.

Furthermore, GRASP can issue alerts for temperature mismatches when the booking temperatures in TOS do not align with the actual set points on the reefer. This capability also helps confirm the reefer rack locations of refrigerated containers. While TOS may indicate that a reefer is in a specific slot, GRASP can verify this when the container connects to the monitoring system. Suppose the expected container ID from TOS does not match the one the monitoring device discovers in that slot. In this case, GRASP will send an immediate alert to indicate that a problem exists and corrective action is necessary.

This is managed through real-time data communicated from each connected reefer within the terminal’s GRASP monitoring environment.

Wrapping it up.

Adding an RTE Remote Reefer Monitoring system and integrating it into your existing Terminal Operating System (TOS) is possible. It’s also an intelligent way to manage your operation more efficiently, increase profitability, and deliver higher customer value to grow your business.

We can help you get started. Take the Next Step

Find out more by reading these articles.

- What is remote reefer monitoring?

- How does remote reefer monitoring work?

- What are the benefits of remote reefer monitoring?

- Where is remote reefer monitoring used?

- How to choose a reefer monitoring system.

Contact RTE to learn how a customized remote reefer monitoring solution can help your reefer terminal provide better value and grow.

Did you like what you just read?