Aligning temperatures with booking set points

Protecting refrigerated cargo quality and reefer terminal interests.

Is there anything more frustrating to a terminal operator than offloading refrigerated containers only to discover that the temperature settings do not match the intended booking set points? This can happen for several reasons and at any point throughout the cold-chain journey, most often outside the boundaries of the reefer terminal. Nonetheless, these mismatches can’t be overlooked as a terminal operator, as the quality of perishable cargo and ultimately the terminal’s reputation are at stake.

Why is it important to align reefer temperatures with booking set points?

First, it’s everyone’s responsibility. Maintaining reefer temperature setpoints to match the booking temperature is crucial for the success of seaborne reefer container shipping and ensures the integrity of refrigerated transport.

Booking temperatures vary from load to load, depending on the refrigerated cargo being shipped. Some perishables, like frozen vegetables, can tolerate wide temperature ranges and still maintain good quality as long as they remain frozen. Other, more delicate products, such as pharmaceuticals and bananas, require precise temperature control throughout their journey to avoid spoilage.

It’s important to note that the terminal operator does not set the booking temperature. Instead, the shipper determines the booking temperatures. The set point is generally configured by the party responsible for loading the cargo into the container by entering the relevant data into the reefer’s control panel. Nonetheless, it remains the terminal’s responsibility and best interest to ensure that each reefer arriving in the yard is correctly configured for its specific temperature requirements.

Why should the terminal care about matching the reefer temperature to the booking set points?

There are several reasons for maintaining setpoint accuracy.

- Cargo Quality and Safety— All cargo stakeholders from origin to the end-user and all carriage points in between count on each refrigerated load arriving safely at its destination and in the best possible condition. The cold chain is only as good as the procedures in place at each link. Terminals, for their part, can ensure their safety by enforcing best practices for checking reefer temperatures and booking set point requirements.

- Regulation Compliance—Protecting perishable goods from spoilage is so crucial to human health that many governing bodies have enacted regulations to prevent the introduction of pathogens resulting from poor cargo handling practices. Maintaining accuracy between the temperature the shipper determines is optimal for the cargo, and the reefer settings are critical to avoid potential fines and delays. No matter what happens before the reefer lands on the terminal or what happens after, the terminal operator can at least ensure that everything is correct on their watch.

- Energy Efficiency – Improper temperature settings can lead to inefficient use of a terminal’s electrical power. Refrigerated loads require more unit cycling to maintain temperature than frozen loads. Therefore, when temperatures are set incorrectly at the reefer, electrical consumption may suffer, exposing the terminal to higher energy costs.

- Customer satisfaction – When setpoints are adjusted according to the booking temperatures specified by the shipper, perishable goods are delivered in optimal condition, ensuring trust and maintaining long-term business relationships.

Why do cargo booking temperatures sometimes vary from the actual setpoints on the reefer container?

Human error accounts for most temperature mismatches, with data often entered manually through each reefer’s controller interface. Some common errors may include transposing numbers, such as -12º for 21º, misinterpreting instructions for Celsius in Fahrenheit, or entering correct data into the wrong reefer.

How long does it take to recognize reefer setpoint and booking temperature mismatches?

Discrepancies are likely to go unnoticed until the reefer reaches its destination. If the refrigerated container is functioning properly, it will continue to maintain the set temperature, even if that temperature is incorrect. By the time it arrives, the cargo may be completely spoiled. The cargo owner will certainly file loss claims for compensation.

How does automated reefer monitoring help protect terminals against claims for loss of refrigerated cargo?

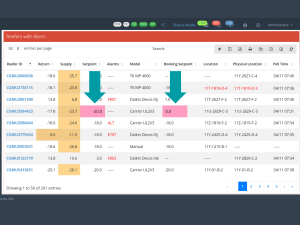

GRASP automated reefer monitoring and TOS integration instantly recognizes these mismatches as soon as the reefer is connected to the monitoring system. Alert notifications are sent to configurable parties on your team to ensure fast and efficient action, protecting the cargo in your care.

Adjusting setpoints to match the booking information is easy. GRASP’s remote access to each connected reefer enables operators to update temperature configurations accordingly from anywhere.

All events are time-stamped, providing verifiable proof of how the container arrived at the terminal and the subsequent actions taken by your team to address the issue. This is essential digital documentation for protection against false cargo claims if the reefer arrives at its final destination damaged. Thousands, if not tens of thousands of dollars, are at stake, and fingers will be pointed for compensation.

GRASP is designed with the terminal operator in mind. It protects the terminal’s interests and delivers a tool for improved temperature management. It features alarms, notifications, and remote control capabilities that minimize exposure to claims losses, enhance efficiency, and reduce costs.

Set point comparisons are just the tip of the iceberg when it comes to the advantages of automated reefer monitoring. Are you ready to discover its full range of benefits?

Get started here and never miss another alert.

Latest blog posts

RTE Reintroduces the RTEL Brand of Temperature Indicators and Data Loggers

See how RTE is strengthening cold‑chain visibility across pharmaceuticals, food, and agriculture.

Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment exposes every gap in your cold chain. With risks like rejected cargo or re‑exports, “good enough” monitoring isn’t enough. Here’s how technology can close those gaps and deliver the documentation accuracy you need to succeed.

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.