Are terminals spending too much on electricity?

With reefers accounting for as much as 40% of a container terminal’s total energy consumption, even relatively small overages can result in significant cost spikes.

Let’s talk about how this happens and how reefer monitoring can help terminal operators better manage their energy usage and costs. That’s right. The same reefer monitoring that delivers automated temperature data can also be your ally in managing energy use. Here’s how.

Reefer containers are like giant refrigerators for shipping perishable foods and products worldwide. Like a kitchen refrigerator, each cycle on and off to maintain a specific temperature. The busy reefer terminal may have hundreds, and even thousands, of these reefers at a time, which can dramatically impact energy consumption. In addition, recent reports indicate that the refrigerated container market is expected to grow by 6% CAGR by 2029, putting even more pressure on terminals and their electrical needs.

How do reefers affect a terminal’s electrical energy needs?

Before controlling energy costs, it’s crucial to understand how electrical use is managed at the reefer terminal. Here are some examples:

- Environment: Fruit exporters have a significant role in refrigerated container traffic, especially in tropical environments where departure terminals deal with hot ambient temperatures. Maintaining specific reefer temperature set points in this environment requires significant energy use.

- Storage: Power requirements increase as stored reefers accumulate in the discharge port awaiting their assigned vessel. This backlog of reefers can also occur within destination ports and transshipment hubs, especially during peak season traffic.

- Hot Boxes: Reefers not pre-cooled by the exporter present more issues. When hot boxes arrive at the terminal in large numbers and connect to electric power simultaneously, it significantly impacts energy use. This also places the financial burden of cooling the containers on the terminal instead of the shipping line.

- Fresh or Frozen Loads: The type of cargo being handled also affects the terminal’s overall power consumption. For instance, bananas require more energy to maintain a chilled temperature than containers of frozen meat or fish, which require considerably less energy to stay at their set temperatures.

- Excessive Handling: Reefers may also be moved multiple times within the terminal, requiring disconnection from power with each move. Prolonged disconnection increases the risk of the internal temperature falling outside the desired range. After repositioning and reconnection, more electricity may be needed to restore the proper temperature.

With this energy use comes the biggest inherent problem that every terminal operator needs to manage – cost. Utilities generally divide the electricity bills of large users, like reefer terminals, into two categories: energy usage and demand.

- Energy usage – This is the base charge the utility invoices the terminal for electrical use. It is the amount of kWh of energy used multiplied by the cost per kWh.

- Demand is an extra cost calculated based on the highest energy usage during a specific period, typically measured in 15-minute intervals. This cost is multiplied by a specific charge based on the terminal’s regular rate structure or bracket. Utilities use this charge to encourage reduced overall electrical use during high-demand periods. This is designed to protect utility infrastructure from damage due to excessive load.

In many cases, terminals surpassing their designated rate brackets during any billing cycle may see their utility rates increase to the next higher bracket for that cycle, regardless of subsequent usage or whether that spike only lasted a short while. Because of this, managers need to pay close attention to their reefer yards and the energy they use, yet they must balance this against the realities of handling perishable cargo.

Reducing reefer energy costs through data.

Given the 30% global increase in electricity costs from 2020 to 2023, tracking electricity usage is crucial for effective cost management.

Terminals can manage these costs through a process called peak shaving. Peak shaving levels out the high peaks of electrical use to reduce spikes in consumption that can lead to higher rates. This can be done by temporarily turning off power to some areas of the operation or switching over to on-site power generation during periods of high demand. To do this effectively, it’s essential to understand how the energy in the terminal is being used.

WRAD II Wireless Reefer Monitoring

This is where reefer monitoring can play a huge role. In addition to temperatures, site-based reefer monitoring systems inherently capture electrical usage data from each connected reefer. When collected information is processed through a managed software platform like RTE’s GRASP system, visual graphs and historical reports can effectively illustrate how electricity is consumed throughout the terminal. Breaking down this data into specific racks and individual containers allows for better decision-making regarding when and how to manage terminal energy allocations.

Using reefer power monitoring as a revenue stream.

An increasing number of shipping lines are investing in the latest designs of refrigerated containers, steering the industry toward a more efficient future. These new models are highly efficient, consuming less energy than older versions while maintaining a more precise temperature range.

GRASP Power Monitoring | Yard View

Instead of relying on flat-rate electrical invoicing, terminals can now implement a fairer and more equitable invoice structure by monitoring actual electrical usage. To adopt this billing method and provide accurate revenue-grade data, terminals will need a calibrated and traceable system that measures usage at the power outlet.

RTE’s RRCE-PM (Power Monitoring) system allows terminals to accurately measure electrical consumption at the power outlet for each reefer slot in the yard. The RRCE-PM can function as a stand-alone system or be integrated with existing RTE reefer monitoring products. Its compatibility with the terminal’s Terminal Operating System (TOS) ensures seamless invoicing management, aligning with established terminal practices.

In conclusion

Managing costs in the reefer yard is challenging without clear information about current electrical usage. The initial step is to understand the terminal’s energy consumption for reefers—specifically, how much energy is being used, where the usage is highest in the yard, and when it occurs most frequently. After gathering this data, it should be analyzed against the utility’s cost structure. Finally, developing a framework for managing excessive energy use during peak demand periods is essential, which may include implementing peak-shaving practices.

RTE can assist terminals in controlling their energy costs by providing a standalone power monitoring system or integrating it with a comprehensive temperature monitoring environment for effective reefer management.

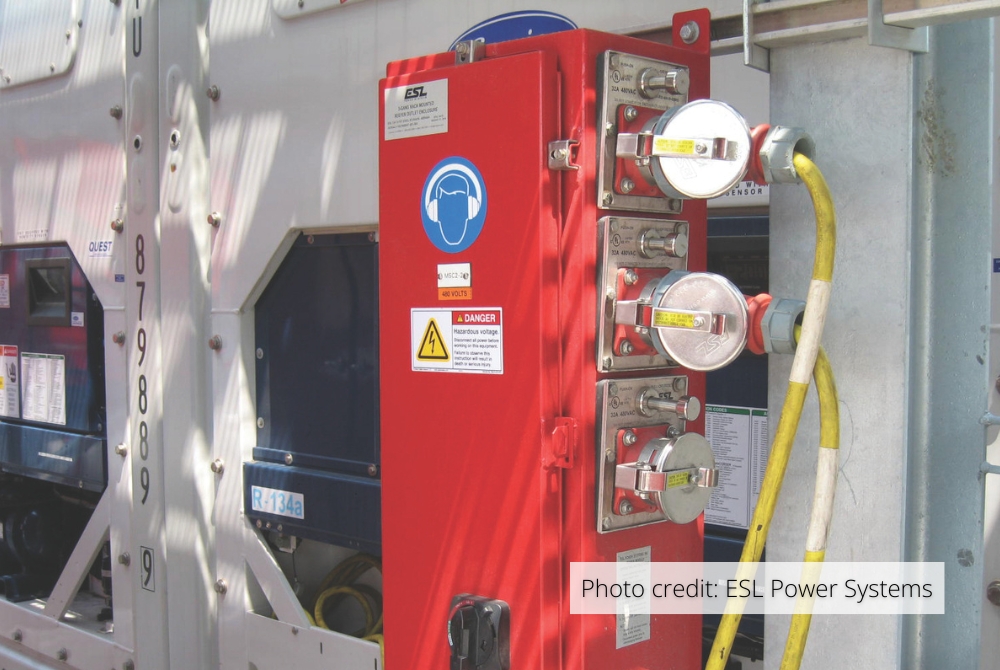

Header image photo credit: ESL Power Systems

Latest blog posts

RTE Reintroduces the RTEL Brand of Temperature Indicators and Data Loggers

See how RTE is strengthening cold‑chain visibility across pharmaceuticals, food, and agriculture.

Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment exposes every gap in your cold chain. With risks like rejected cargo or re‑exports, “good enough” monitoring isn’t enough. Here’s how technology can close those gaps and deliver the documentation accuracy you need to succeed.

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.