Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out.

Reefer volumes are climbing, compliance is tightening, and shipper expectations are shifting fast. The cold chain isn’t niche anymore — it’s the battleground for competitive advantage.

Reliability, visibility, sustainability, compliance, and partnerships — these are the five levers of reefer success. Operators who invest now won’t just keep pace; they’ll own the market by 2030.

Let’s break it down.

The reports are in, and the message is clear – the global reefer container market is growing. Currently sitting at USD 21B this past year (2025), some news outlets are suggesting it will rise to USD 28B by 2030. That’s a forecast CAGR of almost 6% over the next 5 years. There are many reports to review, and each shows different numbers, but all indicate significant increases in cargo volumes over the foreseeable future.

Why should this matter?

Professionals like you are already keenly aware of the trends without even reading the data. You can see it in your yards and feel it under the pressure of managing the current volume. But according to these numbers, it’s not letting up any time soon.

Growth isn’t slowing — it’s accelerating. For reefer operators, that means opportunity, but also risk.

Capacity & Reliability

One failed plug can mean millions in spoiled cargo — and a reputation hit that lasts years.

As you know, unlike dry boxes, refrigerated containers require constant attention. They need infrastructure to sustain them. They need to be monitored for temperature variances that affect cargo conditions and quality. As volumes increase, the need for plugs, yard space, racks (if possible), and backup electrical power for cargo security becomes increasingly critical.

Reputation is everything. Safe cargo throughput, backed by transparent data, is a competitive differentiator as terminals compete for market share. Accurate, real‑time collection is essential for success. But with rising volumes comes greater risk — and one failure can undermine years of trust.

Reliability is not optional any longer—it’s the ticket to play. Fortunately, there are available tools that provide the visibility you need to ensure success.

Technology & Visibility

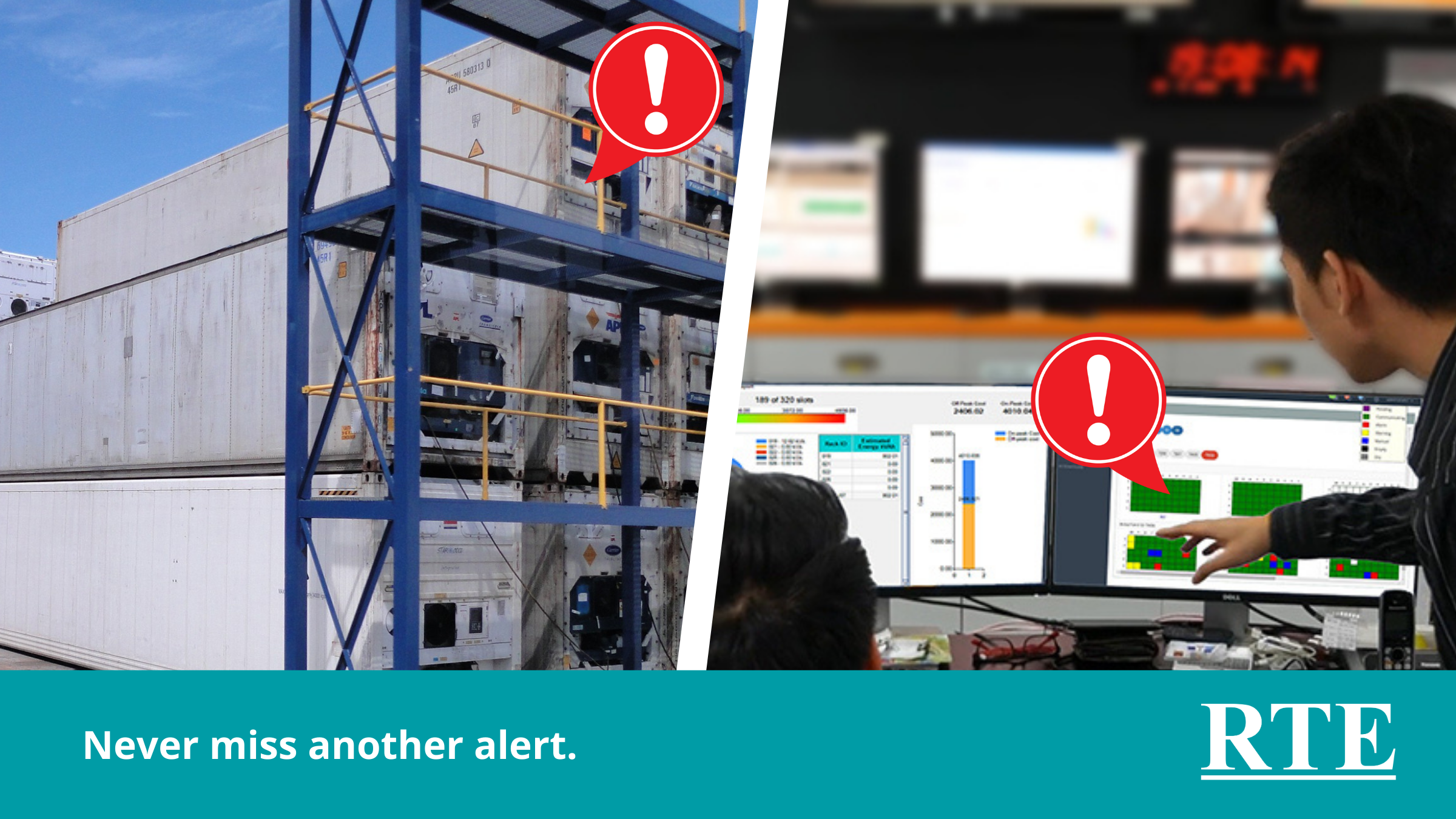

In the past, the only way to keep track of reefer temperature variations was to physically visit each reefer in the yard and manually record the data. This practice is ripe for error and long delays in reporting conditional changes. Unfortunately, many still rely on this method. As reefer throughput increases, the strain on managing the flow increases.

Here’s where operators must step up. Reefer monitoring technology provides instant 24/7 insight into the condition of every reefer in the yard. Data is collected at each reefer point and remotely visualized, enabling teams to manage through remote user interfaces.

Smart reefer handling isn’t a luxury; it’s the new baseline for reefer management.

Through reefer monitoring technology, terminal operators can more reliably prevent cargo spoilage and reduce claims losses. It provides a detailed analysis of energy use across the yard for better electricity cost control.

Integrating this collected data into existing TOS systems increases tracking, improving overall operational efficiency.

Sustainability & Energy Efficiency

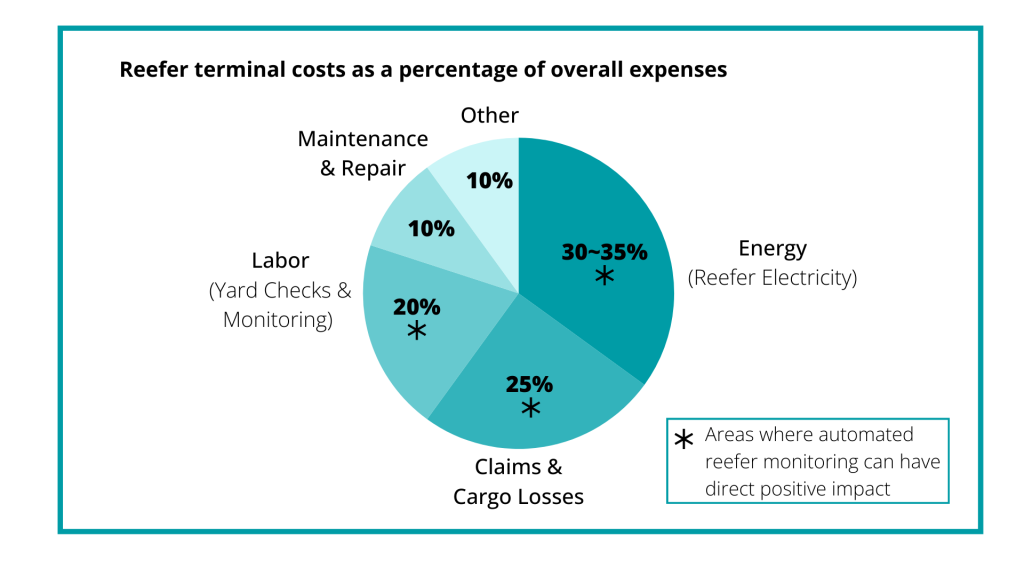

In a typical reefer terminal, energy and claims dominate expenses — together accounting for 65% of total costs. Remote monitoring directly addresses both, making it one of the most impactful investments for operators.

The chart below illustrates how automated reefer monitoring delivers value across four key cost centers. By optimizing energy use, reducing claims through real-time alerts, and automating routine checks, your operation is better equipped to implement cost-saving practices like peak shaving and redeploy your workforce to higher-value tasks.

Energy and claims alone represent nearly two-thirds of reefer terminal costs — and both are directly addressable through reefer monitoring automation. Add in labor for routine checks, and suddenly 80% of a terminal’s costs can see significant efficiency gains by taking this next step.

Service Reliability & Compliance

Precision isn’t marketing-it’s regulation. But it can feel like marketing all the same.

Pharmaceuticals and other high-value, temperature-sensitive products are highly regulated to ensure safety and compliance. Terminal operators are essential assets for handling these critical cold-chain shipments and remain trusted partners in their secure transport.

Digitally collected from automated reefer monitoring provides validated, time-stamped clarity for event response, allowing your team to showcase results during compliance audits confidently.

Strategic Partnerships

The digitally documented success of your team, achieved through reefer monitoring technology, can and should be shared. It provides your sales team with a competitive advantage over neighboring terminals, helping you win new business, retain existing customers, and ensure continued growth.

This isn’t theory – it’s already reshaping shipper expectations. Terminals that get on board early will benefit from this changing environment.

In conclusion

2026 isn’t just another year — it’s the turning point for reefer operators. Rising cargo volumes, stricter compliance demands, and shifting shipper expectations make the cold chain the battleground for competitive advantage.

By investing in automated monitoring, energy optimization, and data-driven service reliability, terminals can move beyond participation to leadership. And that’s where RTE comes in. We help you connect refrigerated containers to the world — with confidence that cargo is maintained and reporting is ready when challenged.

The opportunity is real. The tools are available. The time is now. Are you ready to take command of a $28 billion market? Let’s do this together.

Latest blog posts

Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment exposes every gap in your cold chain. With risks like rejected cargo or re‑exports, “good enough” monitoring isn’t enough. Here’s how technology can close those gaps and deliver the documentation accuracy you need to succeed.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.

Why Reefer Techs Trust RTE with Complex Controller Repairs

Reefer service techs are pros at diagnosing and fixing mechanical and electrical issues in mobile refrigeration systems. But electronic controllers? That’s a whole different ball game.

Reefer Monitoring: A Smarter Way to Build Trust

What if your reefer data could do more than just keep you informed? Often seen as an internal tool—reefer monitoring, can become a powerful customer-facing asset. Here’s how.