Why Reefer Techs Trust RTE with Complex Controller Repairs

Save thousands and skip the guesswork with expert remanufacturing that goes beyond basic repairs.

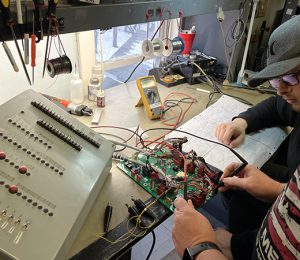

Reefer service techs are pros at diagnosing and fixing mechanical and electrical issues in mobile refrigeration systems. But electronic controllers? That’s a whole different ball game. These units are packed with intricate boards and components that require specialized tools, deep documentation, and serious bench time to diagnose, repair, and test. Most service centers simply don’t have the resources to handle that level of complexity—so when a controller fails, they’re often stuck buying brand-new replacements —OUCH!

We remanufacture electronic reefer controllers for a fraction of the cost of new ones. Our typical price is around $295, depending on the model—compared to OEM replacements that can run $1,000 to $2,000 or more. Those savings add up fast, helping service centers protect margins and reduce waste.

But this isn’t just a quick fix.

Our reman process starts with a full bench teardown and deep cleaning. We inspect every component, replace anything broken or worn—including overlays and screens—and proactively swap out parts that are prone to failure. Then we run rigorous real-world simulations to ensure your controller performs like new. And we back it all with a one-year warranty.

Thanks to four decades of remanufacturing expertise, our controllers often outlast the originals. What you get back isn’t just repaired—it’s rebuilt to perform.

Ready to reman your controller?

Latest blog posts

Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment exposes every gap in your cold chain. With risks like rejected cargo or re‑exports, “good enough” monitoring isn’t enough. Here’s how technology can close those gaps and deliver the documentation accuracy you need to succeed.

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.

Reefer Monitoring: A Smarter Way to Build Trust

What if your reefer data could do more than just keep you informed? Often seen as an internal tool—reefer monitoring, can become a powerful customer-facing asset. Here’s how.