Your Biggest Cold Treatment Vulnerability Isn’t Temperature—It’s Documentation

Cold Treatment has quietly become one of the most demanding processes in the global cold chain. What used to be a niche requirement for select commodities is now a growing operational pressure point for terminals and carriers. And with that growth comes a simple truth: Cold Treatment can’t fail — and neither can the systems that support it.

As more fresh produce moves through ports under strict phytosanitary protocols, terminals are being asked to deliver something that’s harder than it sounds: uninterrupted temperature control, continuous documentation, and zero tolerance for deviation. In an environment where labor is tight, reefer volumes are rising, and customer expectations are higher than ever, the old way of monitoring reefers simply isn’t enough.

This is where the conversation is shifting — and where technology is stepping in.

Why Cold Treatment Is Different

Most reefer cargo needs stability. Cold Treatment needs precision.

A standard reefer load can tolerate routine monitoring intervals and basic temperature logs. Cold Treatment, on the other hand, is a regulated process designed to eliminate pests through sustained low temperatures over a defined period. If the temperature drifts — even briefly — the entire treatment can be invalidated.

That means:

- No blind spots

- No delayed alerts

- No missing data

- No “we’ll check it on the next round”

Cold Treatment doesn’t care about operational constraints. It only cares about compliance.

And that’s exactly why terminals are rethinking how they monitor these units.

Regular Reefer Monitoring vs. Cold Treatment

Regular Reefer Cargo

- Stable temperature maintenance

- Standard monitoring intervals

- Basic logs for quality assurance

- Operational focus: efficiency and throughput

Cold Treatment Cargo — What It Really Means

Cold Treatment (CT) is not just a temperature setting — it’s a phytosanitary protocol required by many countries to eliminate pests such as fruit flies in fresh produce.

The process requires holding cargo at a specific low temperature for 10–24 days, depending on commodity and destination.

Cold Treatment involves these practices:

- Strict, continuous temperature control with zero tolerance for power or monitoring gaps

- Remote monitoring and rapid intervention to eliminate risk

- Regulatory compliance tied to pest‑eradication standards

- Detailed trip reporting for full traceability

Common Cold Treatment commodities include:

- Citrus / Apples / Grapes / Stone fruit (peaches, cherries, apricots)

Bottom Line: Cold Treatment demands a level of precision and documentation that manual processes simply can’t guarantee.

The Operational Reality: Manual Monitoring Isn’t Built for This

Terminals have always done their best with manual reefer rounds. But Cold Treatment exposes the limitations of that model:

- Technicians can’t be everywhere at once

- Logs can be incomplete or inconsistent

- Deviations may go unnoticed until it’s too late

- Power interruptions aren’t always caught in real time

- Documentation for regulators and customers is often fragmented

Cold Treatment magnifies every gap in the process. And when the stakes include rejected cargo, re exports, or fumigation, “good enough” monitoring simply isn’t good enough anymore.

The Hidden Burden: USDA Reporting

Beyond the temperature curve itself, Cold Treatment comes with a significant administrative load. Terminals must provide the USDA with complete digital records for every Cold Treatment unit.

Without automation, this requires technicians to walk the yard, plug into each reefer individually, download the data, transfer it into the terminal’s system, organize it, and send it onward — a time‑consuming, labor‑heavy process that strains already stretched teams.

GRASP removes that burden by enabling remote Cold Treatment data downloads and automatic record creation, ensuring terminals stay compliant without the manual grind.

Why Automated Monitoring Is Becoming the New Standard

Across the industry, there’s a clear shift toward automation — not as a luxury, but as a necessity. Terminals want fewer risks, fewer manual steps, and fewer surprises. They want visibility that doesn’t depend on someone being in the right place at the right time.

This is where RTE’s GRASP reefer monitoring platform changes the equation.

GRASP gives terminals the ability to monitor Cold Treatment units with the precision the process demands — automatically, continuously, and without blind spots.

How GRASP Strengthens Cold Treatment Operations

→ Continuous, Automated Monitoring – Cold Treatment requires uninterrupted temperature validation. GRASP delivers real‑time visibility 24/7, ensuring deviations are caught the moment they occur — not hours later.

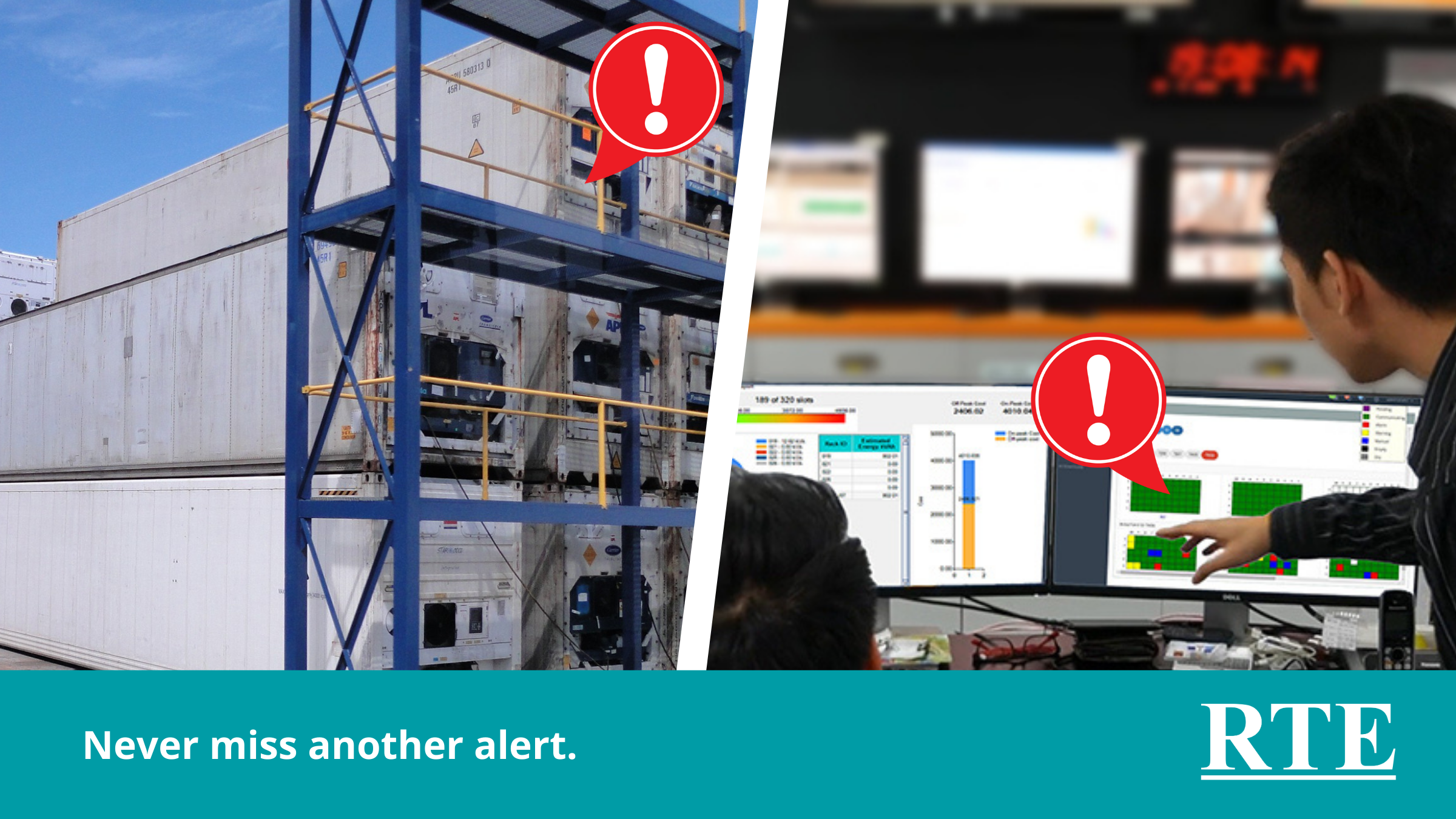

→ Instant Alerts for Temperature or Power Issues – When something goes wrong, every minute matters. GRASP sends immediate alerts so technicians can act before the treatment is compromised.

→ Complete Digital Reporting – Cold Treatment is a compliance‑driven process, and every degree must be documented. GRASP automatically captures and stores all temperature data throughout the treatment window, creating a continuous digital record.

→ Remote Cold Treatment data downloads provide a complete audit trail that terminals can easily share with carriers, authorities, and customers — without manual paperwork or gaps in the log.

→ Seamless Integration With Terminal Operating Systems – Terminals don’t need another silo. GRASP integrates directly into existing TOS environments, giving operators a unified view of reefer status across the yard.

→ Reduced Operational Risk – By automating monitoring and documentation, GRASP reduces the chance of human error, missed checks, or incomplete logs — the very issues that put Cold Treatment at risk.

The Bigger Picture: Cold Treatment Is Growing — and Expectations Are Rising

As global trade evolves, more commodities are moving under Cold Treatment requirements. Regulators are tightening standards. Customers are demanding transparency. And terminals are being asked to deliver reliability at a scale that manual processes simply can’t support.

The terminals that succeed will be the ones that embrace automation — not just to keep up, but to lead.

Cold Treatment is a high‑stakes process. It deserves high‑precision monitoring.

RTE’s Role in the Future of Cold Treatment

RTE isn’t just offering a tool. We’re helping terminals modernize how they manage one of the most sensitive, high‑risk cargo types in the cold‑chain. GRASP gives operators the confidence that every Cold Treatment unit is monitored, documented, and protected — from the moment it enters the yard to the moment it leaves.

Cold Treatment demands precision. RTE delivers it — automatically, continuously, and without compromise.

Ready to strengthen your CT operations?

Latest blog posts

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.

Why Reefer Techs Trust RTE with Complex Controller Repairs

Reefer service techs are pros at diagnosing and fixing mechanical and electrical issues in mobile refrigeration systems. But electronic controllers? That’s a whole different ball game.

Reefer Monitoring: A Smarter Way to Build Trust

What if your reefer data could do more than just keep you informed? Often seen as an internal tool—reefer monitoring, can become a powerful customer-facing asset. Here’s how.