Consider joining our growing group of informed professionals. Sign up for our newsletter and stay up to date with all the action. Sign Up Now.

Take Command in ’26 – Positioning for a $28B Reefer Market by 2030

2026 isn’t just another year — it’s the year reefer operators either plug in or get left out. Operators who invest now won’t just keep pace; they’ll own the market by 2030. Let’s break it down.

The Smart-Yard Framework: 4 Questions to Guide Your 2026 Reefer Strategy

Ask yourself: “What type of reefer operation are we building?” This important first step tees up this 4-part framework for making smarter, scalable decisions regarding your reefer business.

Why Reefer Techs Trust RTE with Complex Controller Repairs

Reefer service techs are pros at diagnosing and fixing mechanical and electrical issues in mobile refrigeration systems. But electronic controllers? That’s a whole different ball game.

Reefer Monitoring: A Smarter Way to Build Trust

What if your reefer data could do more than just keep you informed? Often seen as an internal tool—reefer monitoring, can become a powerful customer-facing asset. Here’s how.

Reefer Monitoring: Myth vs Reality

“Why does the lettuce look like soup?” If you’ve asked that question—or fielded it from a customer—it might be time to rethink your reefer monitoring strategy. Let’s bust these 5 myths.

How Remote Reefer Monitoring Works

What is automated reefer monitoring, and why does it matter to marine terminals? Let’s break down the system architecture and its benefits to terminal operations.

The Road to Automation for Small Terminals

Does terminal automation seem like too big a leap, especially if you’re a small reefer terminal operation? Consider starting with this easy first step that delivers measurable results and low upfront investment.

How to stay competitive in reefer terminal container handling

Relevancy is crucial in how your customers perceive your business. Let’s consider a few ideas on how to remain competitive in refrigerated transport.

Top 5 Benefits of Remanufactured Reefer Controllers

Our bets are on #5 as being the most popular. What say you?

Mismatched – the mystery of set point disparity in reefers.

Is there anything more frustrating to a terminal operator than offloading refrigerated containers only to discover that the temperature settings do not match the intended booking set points?

Ready to hit your reefer targets?

Including reefers in terminal operations can yield huge benefits. Embrace these challenges, and success will happen.

Reefer trends: Rising throughput – Are you prepared?

The reefer shipping market will grow by almost 6% each year for the next 5 years. Relying on traditional reefer management methods is no longer sustainable.

The ROI of Reefer Monitoring: Pt 1 – Reducing Loss Claims

Cargo loss claims – A big profit suck or an avoidable cost? What causes them, and how do they affect terminals financially?

The Art of Communicating Reefer Yard Work Orders

Is notification fatigue preventing critical messages from reaching your team? Cut through the noise with visual cues.

Power Monitoring for Terminals

Are terminals spending too much on electricity? Reefer monitoring can fix that. Here’s how.

Worker safety and reefer monitoring

Slips, trips, and falls. How reefer terminals can improve safety while simultaneously increasing efficiency and profitability by avoiding these safety-related incidents.

Who’s watching the reefers in your terminal yard?

Data loggers enable eyes from outside container terminals to view cargo. Here’s why reefer operators like you should care and how to protect your business.

RTE wireless reefer monitoring system for the Port of Thessaloniki

ThPA S.A. is bolstering its reefer container handling capabilities by adding RTE’s GRASP automated reefer monitoring platform across 400 reefer points. Read more.

When is the right time to consider a reefer monitoring system?

Every refrigerated container terminal is different. Knowing when it’s right to add automated reefer monitoring comes down to a few key thoughts. Let’s explore them.

Let’s talk about reefer terminal safety

In honor of National Safety Month, let’s consider the safety of reefer terminal workers and the process of manual container temperature monitoring.

Six things that keep reefer terminal operators up at night.

Many things keep reefer operators up at night. Can you relate? Let’s identify some and offer a cure to ensure better outcomes and more restful nights.

Avoid cargo loss claims with these 3 practices.

Reefer operators can protect their interests and their wallets while avoiding costly and perhaps unjustified cargo loss claims. Here are 3 to get started.

Five steps for taking control of challenges to growth.

Changes in reefer demand provide opportunities for terminals. However, unchecked challenges can limit the growth potential. Here’s one terminal’s experience.

The key ingredient to growing your reefer terminal is …

Terminal space and access to plugs are excellent first steps to increasing reefer throughput. But don’t forget the key ingredient to grow your business.

True or False: Reefer monitoring is only about temperature.

Temperature monitoring is a critical aspect of remote reefer monitoring. But is it the only one? Here’s what else it delivers for the shrewd reefer terminal operator.

How to use RRM to GROW your reefer business.

Share data from remote reefer monitoring (RRM) as a deliverable to grow your business. The under-estimated outward benefit of reefer monitoring.

The case for site-based reefer monitoring

Site-based reefer monitoring systems offer terminals autonomous access to immediately manage data from any reefer type, regardless of its model or association.

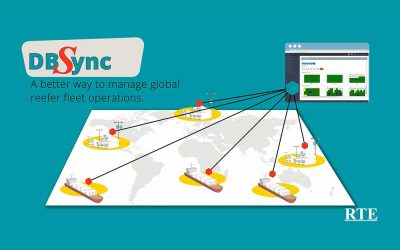

DBSync offers visibility across worldwide reefer operations

DBSync connects reefer data from vessels and terminals at multiple locations into a single viewing platform, a reefer monitoring solution for global operations.

Integrating Terminal Operating Systems (TOS) with Remote Reefer Monitoring

In today’s world of container shipping logistics, keeping track of workflows and information is essential to maintaining necessary efficiencies.

How to choose a reefer monitoring system for your operation

Communication between client and provider is critical to understanding and solving the client’s main pain points. We start by asking these fundamental questions.

Reefer data automation for accuracy, efficiency, and safety

Automated monitoring and data collection presents today’s modern reefer terminal with opportunities to improve worker safety, efficiency, and data accuracy.

Who benefits from remote reefer monitoring?

These are some of the people that benefit from remote temperature monitoring of refrigerated containers. And it’s not just marine reefer terminals. Are you one of them?

What are the benefits of remote reefer monitoring?

Automated and remote temperature monitoring of refrigerated containers, called reefers, provides multiple benefits to port terminal operators that lead to business growth.

What is Remote Reefer Monitoring?

Automated reefer monitoring protects refrigerated container transportation through remote access to temperature data, alerting operators to changes that can affect perishable cargo.

Offset high energy costs with revenue-grade power monitoring

Revenue-grade power monitoring of refrigerated containers allows reefer terminals to offset electrical use as a revenue stream. The RTE RRCE-PM system ensures accuracy for precise customer billing.

How does remote reefer monitoring work?

Reefer monitoring protects refrigerated container transportation through remote access to temperature data, alerting operators to changes that can affect perishable cargo.

Where remote reefer monitoring is used

The ability to remotely monitor the condition of refrigerated containers is nearly unlimited. As a result, vessels and port terminals of any size can benefit from an effective reefer monitoring solution.

Is remote reefer monitoring suitable for my business?

Some refrigerated container terminals may not consider themselves large enough for a reefer temperature monitoring investment. Here’s why it’s right for you.

6 Things You May Not Know About Remanufacturing

Do you have your electronic reefer controllers repaired or remanufactured when broken? If so, you are making a positive impacting our environment – and you may not even know it.

Zuidnatie adds RTE remote reefer monitoring

Container services specialist, Zuidnatie installs RTE’s WRAD wireless reefer monitoring and GRASP data management to their logistics operation.

Why plugs alone are not enough

Unlike dry containers, reefers require more than plugs and real estate. Refrigerated containers and perishable cargo demand attention to detail.

Repaired vs. Used vs. Remanufactured Reefer Electronics

When electronic components on your reefer fleet break, wear out, or stop working, apart from...

5 Reasons to Automate Reefer Monitoring

Why is temperature monitoring of refrigerated containers essential? Unlike dry shipping...

Sogester S.A. Chooses RTE’s GRASP3.0 Reefer Monitoring System

Sogester or Sociedade Gestora de Terminais S.A., a joint venture between APM Terminals and the...

RTE Achieves Navis Ready Validation for GRASP 3.0 Remote Reefer Monitoring System with Navis N4 3.7.5.1

Refrigerated Transport Electronics (RTE), the world leader in Remote Monitoring Solutions for the...

Mersin International Port Chooses RTE’s GRASP Reefer Monitoring System

Automated Reefer Monitoring at MersinMcGraw, NY, April 5, 2017– Refrigerated Transport Electronics...